Silicone Pouch, Keychain, Wallet, Bag, Case, Coin

Workflow

| Product name | Silicone pouch |

| Reference price | 0.5-5USD |

| Number of initial lots | 500PCS |

| Delivery date | 5 days |

| OEM | Possible |

| Producing area | China |

| Others | With packaging |

| Scope of application | It is applied in many cases such as sports fashion design style, unisex, business gifts, advertising promotion, tourism commemoration, etc. |

Product Benefits

Product features:

1. Made of 100% pure silica gel, the fabric is soft, tear resistant and feels great.

2. Naturally harmless, non-toxic and tasteless, non-corrosive, environmental protection.

3. Has waterproof, non-adhesive and super strong wear resistance and strong adhesiveness.

4. Design and color can be ordered according to your needs.

5. LOGO is a combination of Chinese and English characters and designs, and LOGO can adopt indentation, indentation or silk printing.

6. Quality assurance, tension does not deform and does not break.

7. Affordable and guaranteed quality.

Features and advantages of silica gel products

1. High temperature resistance: Applicable temperature range -40 ~ 230 ℃, can be used in microwave oven and oven. The bowls, dishes, and lunch boxes that can hold the microwave are all made of silica gel.

2. Easy to wash: Silica gel products produced by silica gel can be cleaned by washing with water and can also be washed in the dishwasher.

3, Long life: The chemical performance of silica gel material is stable, and the manufactured products have a longer life than other materials.

4, Soft and comfortable: Thanks to the softness of the silica gel material, the cake-shaped product feels good, is highly soft and does not deform.

5, Variety of colors: You can mix different beautiful colors according to your needs. Customize your unique design and

6. Environmental protection Non-toxic: No toxic and harmful substances are generated from the factory of raw materials to the shipment of finished products.

7. Electrical insulation performance: Silicon rubber has a high resistivity, and its resistance value can still be kept stable in a wide temperature range and frequency range. At the same time, silica gel has good resistance to high-voltage corona discharge and arc discharge, such as high-voltage insulators, television high-voltage caps, and electrical components.

8. Low temperature resistance: The critical point of the minimum operating temperature of ordinary rubber is -20 to -30 degrees, but silicone rubber still has relatively good elasticity at -60 to -70 degrees. Some special formulations of silicone rubber can withstand extremely low temperatures such as low temperature seal rings.

9. Conductivity: With the addition of conductive fillers such as carbon black, silicone rubber has good conductive performance, such as keyboard conductive contact points, heating element parts, electrostatic resistant parts, shields for high voltage cables, medical physiotherapy. Therapeutic conductive film and the like.

10. Weather resistance: Ordinary rubber decomposes rapidly under the action of ozone due to corona discharge, silicone rubber is not affected by ozone, and its physical performance is slight for a long time under ultraviolet rays and other climatic conditions. There are only a few changes, such as sealing materials used outdoors.

11. Thermal conductivity: With the addition of some thermal conductive fillers, silicon rubber has excellent thermal conductivity in heat dissipation sheets, heat conductive seal pads, copying machines, facsimile heat conductive rollers, etc.

12. Radiation resistance: The radiation resistance of phenyl group-containing silicone rubber is greatly improved, for example, electrically insulated cables, connectors for nuclear power plants, etc.

| Material | Silicon | MOQ | 300pcs |

| Design | Customize | Sample time | 10 days |

| Colour | Customize | Production time | 30 days |

| Size | Customize | Packing | Customize |

| logo | Customize | Payment terms | T/T(telegraohic transfer) |

| Origin | China | Down payment deposit | 50% |

| Our advantage: | Years of professional experience; integrated service from design to production; rapid response; good product management; quick production and proofing. | ||

Manufacturing Description

The pre-cut rubber material is placed in a press machine with a mold set, and heat and pressure are applied to press it. There are three main types of silicone rubber press molding methods: compression molding, transfer molding, and injection molding.

[Compression molding] (Direct pressure molding) This is a method of molding by placing the rubber material directly on the mold. It is suitable for small lots and has the advantage of low mold costs.

[Transfer molding] (Injection molding) This is a molding method in which the required amount of rubber material is manually poured, and is suitable for manufacturing products that emphasize appearance. Although you can make high quality products, the cost of molds and materials is a little high.

[Injection molding] (Automatic injection molding) Molding is performed using a cylinder that automatically weighs rubber material and injects it into a mold. It is possible to produce in large lots, but the mold cost is higher than transfer molding.

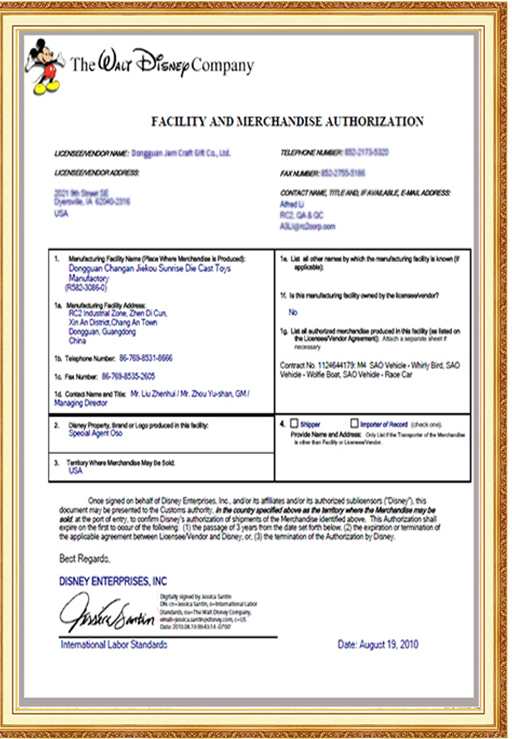

Certificate of Authentication

Products categories

-

Phone

-

E-mail

-

WeChat

Judy

-

Skype

Skype

-

Line

Line

-

Top

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur