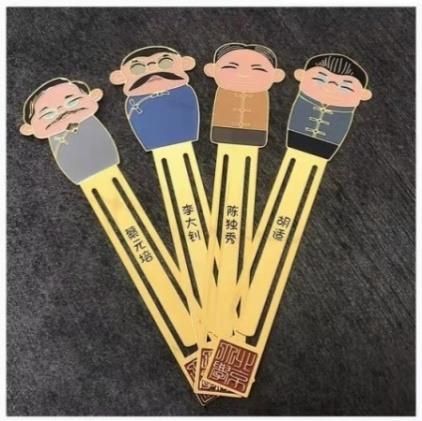

Metal Badge,Metal Pin,custom metal,Clips,School badges

Workflow

| Product Name | Metal Badge/Metal Pin |

| Material | Zinc alloy |

| Reference price |

0.5~3USD |

| Make less orders | 500PCS |

| Delivery date | 5 days delivery |

| OEM | OK |

| Place of production | made in China |

| Other | Including packaging |

There are many kinds of metal badges, including badges, collars, hat badges, shoulder badges, armbands, medals, medals, commemorative badges, badges, etc.

Gold badges are processed with enamel, imitation enamel, baking, engraving, printing, stamping badges. The most popular processes are baking, imitation enamel, stamping, and other processes: engraving (etching), screen printing, offset printing, and 3D effect.

1、 Soft enamel (imitation enamel) badges: these badges are exquisite in workmanship, beautiful in color, exquisite in workmanship and smooth in surface; The surface is flat, and the lines on the surface can be gilded, silvered and other metal colors, with various colors filled between the metal lines; It gives a very upscale and luxurious feeling It is the first choice for badge making process.

2、 Casting: compared with other badges, the surface of this kind of badges is three-dimensional, and these badges are often mixed with soft enamel or baking technology.

3、 Stamping+baking paint+glue drop: this kind of badge has thick substrate from the side, transparent glue drop on the surface, bright color, clear and bright lines, and strong texture; Stamped metal badge surface can adopt various electroplating

treatment.

4、 Stamping+lithography+glue dropping: the substrate of this kind of badges is very thin from the side, and the glue dropping layer is slightly thick; Generally, graphics are relatively simple. Screen printing can be used without gradual change in color. Screen printing is relatively easy to operate. If graphics are simple, they can be used at a lower price than offset printing. However, if graphics have gradual change in color, they can only be printed by offset printing. Generally, after drying, a layer of transparent resin (Poly) will be added on the surface of the pattern to protect thepattern.

5、 Stamping+electroplating: This type of badge is characterized by its metallic surface. It is sometimes used in combination with soft enamel or baking process. Generally, it is made of soft copper (iron is cheaper, but not as beautiful as copper), which is pressed by a hydraulic press at one time. After manual polishing, the badge lines are clear and beautiful.

6、 Corrosion+baking varnish: Bite plate products have the characteristics of fine lines and beautiful overall color, plus a layer of protective resin (Poly) added to the surface of the badge.

7、 Tinplate badge: Tinplate is an iron sheet with a layer of tin on its surface, which is not easy to rust, also called tinplate; The surface pattern is printed.

Badge, what is a badge, logo, badge introduction, badge history

Emblem is the representative or symbol of a kind of thing in an era. It must contain rich historical connotation behind it. Emblem itself is also a handicraft, so it is loved by more and more people. Now it has become a public collection, and badges are one of the indispensable items in the antique and junk markets;

According to different functions, badges can be mainly divided into badges, such as school badges, company badges, and company logos. Medal, a symbol of honor given by the state or unit to a person for meritorious service. Commemorative badges are the most widely issued badges, such as Chairman Mao's commemorative badges, badges for various major events, and commemorative badges for various celebrations. Craft badges, jewelry badges, badges produced purely for decoration.

The badges can be divided into carved badges, electroplated badges, inlaid badges, cast badges, etc. according to the production process.

According to the age, the badges can be divided into early badges before the early years of the Republic of China, middle badges before and after liberation, cultural revolution badges and modern badges.

The badges can be divided into metal badges, porcelain badges, lacquer wood badges, plastic badges, bakelite badges, etc; Metal badges are the most common, plastic badges are not wear-resistant, and their wearing and collection are limited. Emblems made of stainless steel developed in recent years are thin, exquisite, precise in color, bright in surface and resistant to corrosion Copper medallions are generally special commemorative medallions, which are characterized by mellow, rough and precious, especially in red copper, with a king style. Gold badges are the best of badges. They are generally issued in limited quantities for a special commemorative activity The surface of ceramic seal is smooth and bright, corrosion resistant but fragile. Ceramic seals are rare and generally have high artistic and collection value Bamboo seal is superior in production technology, texture, color, etc. It is easy to crack in the dry north.

The ways to obtain badges are to distribute, receive, present, inherit, exchange, purchase and other modern badges, and some badges mainly used as ornaments are also called brooches, badges, lapel pins, lapel pins and lapel pins

Legend description of badge production process, introduction to enamel, imitation enamel, baking varnish, bite plate, printing, stamping badge production process:

The most popular processes are baking varnish, imitation enamel, stamping, and other processes: bitching (etching), screen printing, offset printing, 3D stereoscopic effect, etc

Paint big picture effect. The concave part can be painted with various colors, while the convex part can be painted with various metal colors such as gold and nickel plating.

Baking paint features: bright color, clear lines and strong texture. Copper or iron can be used as raw materials, and iron baking paint badges are cheaper and better. If your budget is small, this is the most appropriate one!

The surface of the baked enamel badge can be coated with a layer of transparent protective resin (Polly), which is commonly known as "glue dripping" (note that the color of the badge will be slightly lighter after the glue dripping due to the refraction of light)

The surface of the imitation enamel badge is flat. The lines on the surface can be plated with gold, silver and other metal colors, and various colors are filled between the metal lines.

The manufacturing process of the imitation enamel badge is similar to that of the enamel badge (cloisonne badge). The difference between the imitation enamel and the real enamel is that the enamel pigments used are different (one is the real enamel pigment, the other is the synthetic enamel pigment)

Enamel like badges have exquisite workmanship, smooth surface, and are particularly delicate, giving a very high-end and luxurious feeling It is the first choice for badge making process If you want to make a beautiful and high-grade badge first, please choose the imitation enamel badge

Stamping badges: Stamping badges are generally made of copper (red copper, red copper, etc.), zinc alloy and iron Because copper is the softest, the line of copper embossed badge is the clearest, followed by zinc alloy, and the price of corresponding copper embossed badge is also the highest

Stamped badges can be plated with various effects, including gold, nickel, copper, bronze and silver plating The concave part of the stamping badge can also be processed into a sanding effect.

Printing badges: divided into screen printing and flat printing It is also called adhesive dropping badge because the final process of badge is to add a layer of transparent protective resin (Boli) on the surface of the badge. The materials used are mainly stainless steel and bronze The copper or stainless steel surface on which the badge is printed is not electroplated, but is natural color or brushed

Screen printed badges are mainly aimed at simple graphics, less colors, and cheaper screen printing plates

Plate printing: for complex patterns and many colors, especially gradient colors,

Concave convex effect of badge surface: baking paint, stamping (the surface can be plated with gold, nickel, etc.)

The surface of the badge is flat: screen printed, cloisonne (enamel), imitation cloisonne (enamel), bite plate, and rotten version badge

The pattern color has a gradual change: offset printing must be used (also called lithography, if the number is small, offset printing and plate making costs will be high). Generally, a layer of transparent protective resin (also called Boli, the surface will be slightly raised) will be added to the surface

Selection of badge materials: copper (recommended), stainless steel, iron (low price, but easy to rust, etc., not recommended), other non-metallic materials (acrylic, organic glass, two-color plate, PVC soft glue, etc., such as acrylic, two-color plate and other water-resistant materials should be used for making bathroom key plates and other places with water);

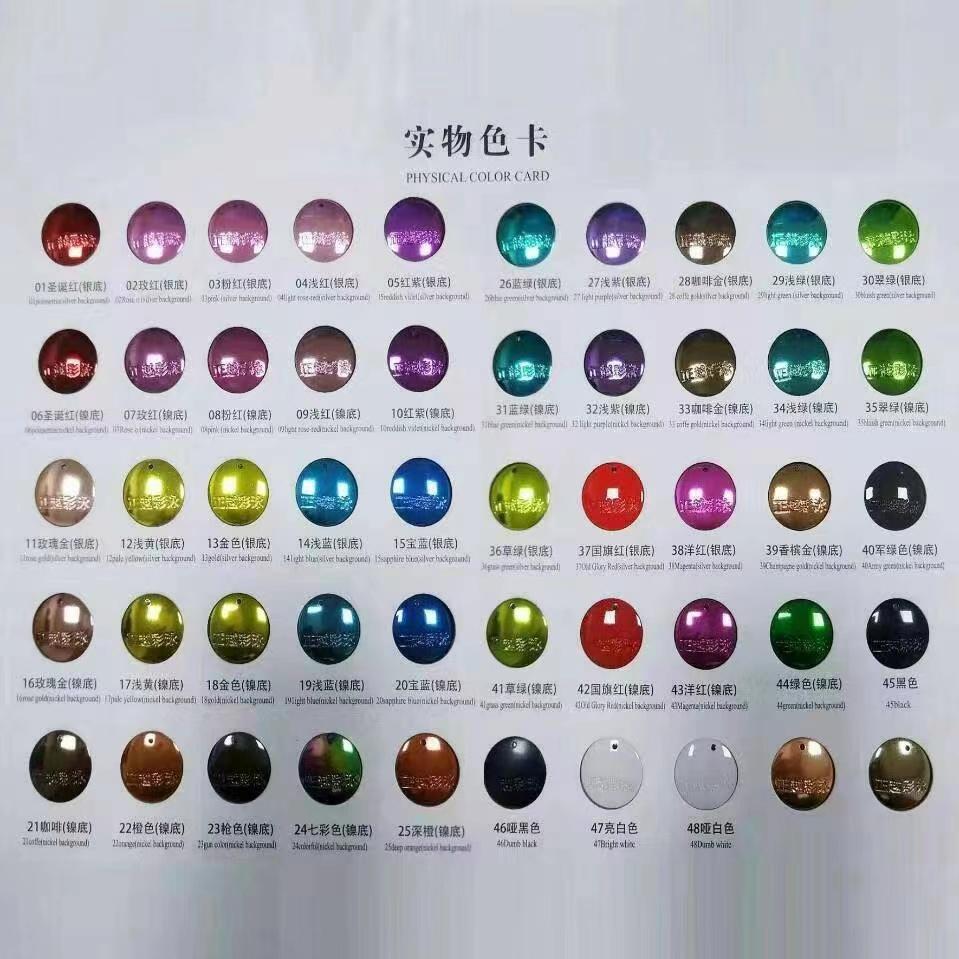

Selection of electroplating surface treatment effect on badge surface: according to different drawings, it can be plated with gold, nickel (silver white), bronze, etc. The surface can be sanded, matte, etc., and a layer of transparent protective resin (also called Poly) can be added;

Selection of badge price: The price is largely determined by the materials, processes and quantity. If the budget is sufficient, please choose a copper badge. If the price is cheap, please choose an iron badge

The general price is enamel>anti enamel>baking varnish, stamping>version biting, bad version, printing;

Suggestions for badge design graphics: The more complex the graphics and the more colors, the higher the price will be. Moreover, many effects cannot be achieved in actual badge production. For example, if the direct spacing of lines is less than 1mm, it will be difficult to handle All graphics should be as simple and generous as possible We need to communicate with our designers constantly before and during the whole process of designing badge graphics The vector graphics software we use is CorelDraw and Illustrator.

Manufacturing process

| Material | Zinc alloy, etc. | MOQ | 300PCS |

| Design | Customize | Sample time | 10 days |

| Colour | Printing | Production time | 30 days |

| Size | Customize | Packing | Customize |

| logo | Customize | Payment terms | T/T (telegraphic transfer) |

| Origin | China | Down payment deposit | 50% |

| Our advantage: | Years of professional experience; integrated service from design to production; rapid response; good product management; quick production and proofing. | ||

Products categories

-

Phone

-

E-mail

-

WeChat

Judy

-

Skype

Skype

-

Line

Line

-

Top

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur